ACREL/安科瑞 品牌

生产厂家厂商性质

无锡市所在地

ARD系列低压电动机保护器

1 概述

ARD系列低压电动机保护器,具有过载、断相、不平衡、欠载、接地/漏电、堵转等保护功能。可与接触器、电动机起动器等电器元件构成电动机控制保护单元,具有远程自动控制、现场直接控制、面板指示、信号报警、现场总线通信等功能。可广泛应用于煤矿、石化、冶炼、电力、建筑等行业的配电领域。

2 产品选型

2.1数字式电动机保护器

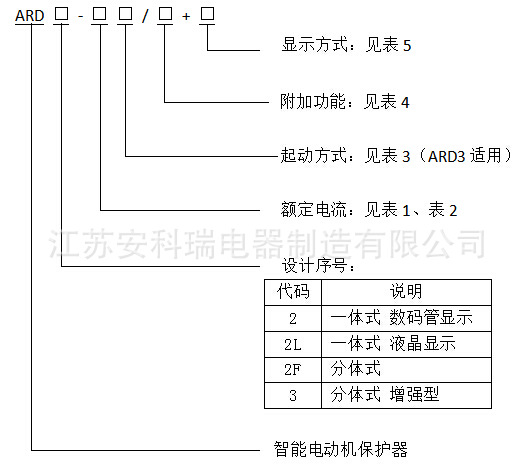

● 型号说明

● 额定电流

表 1

● 额定电流附加说明

表 2

注:>250kW的低压电动机,额定电流小于800A时均可选用800A等级的电动机保护器。

● 起动方式

表 3

注:

1、手动模式:保护器参与控制,起动方式为直接起动(全压起动)、双向起动时,保护器设置为手动模式。

2、两步模式:保护器参与控制,起动方式为星/三角起动(两继电器)、自耦变压器(两继电器)时,保护器设置为两步模式。

● 附加功能

表 4

注:1、“√”表示可以选择的附加功能。

2、温度保护的测量范围:热电阻100Ω~30kΩ。

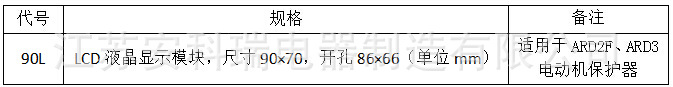

●显示方式

表 5

注:对于无显示要求的客户,在一批订单中订购一个90L显示单元,作为调试使用。

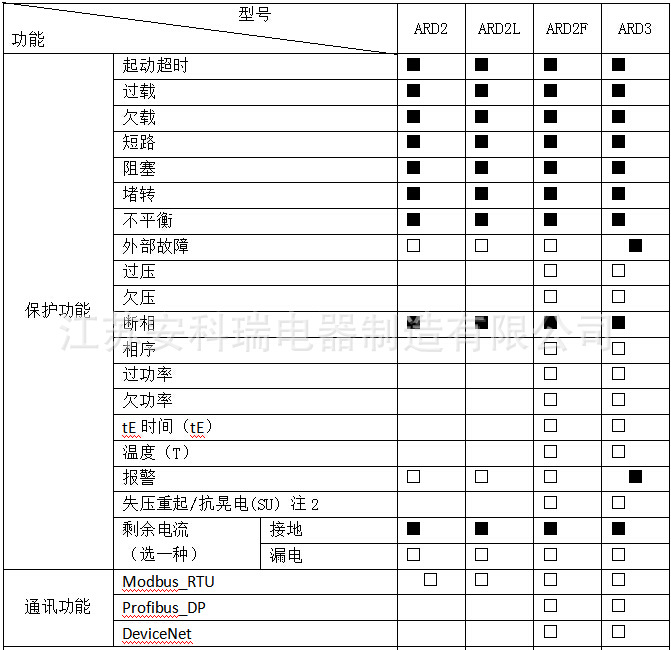

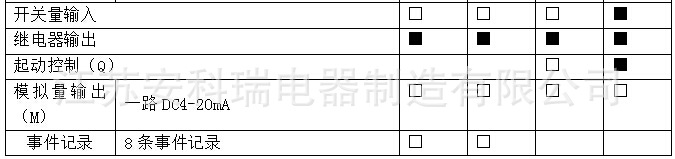

● 产品规格

注:

1、“■”为标配功能,“□”为选配功能。

2、选配失压起重(抗晃电)功能含电压和故障记录功能。

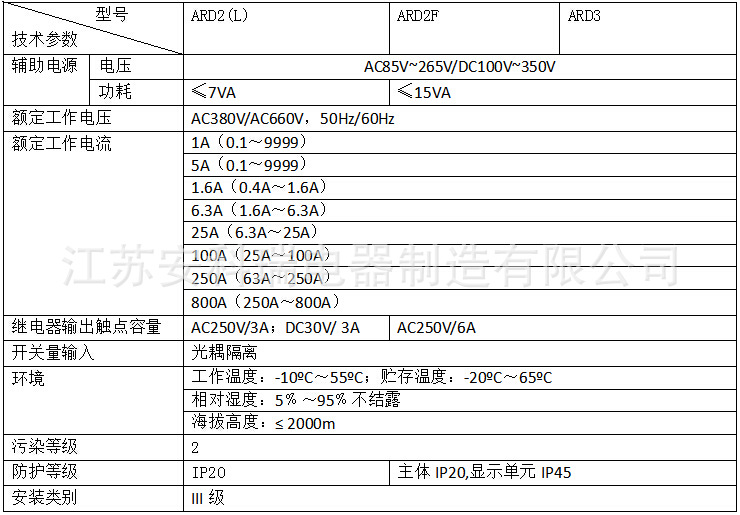

● 技术指标

2.2模块式电动机保护器

● 型号说明

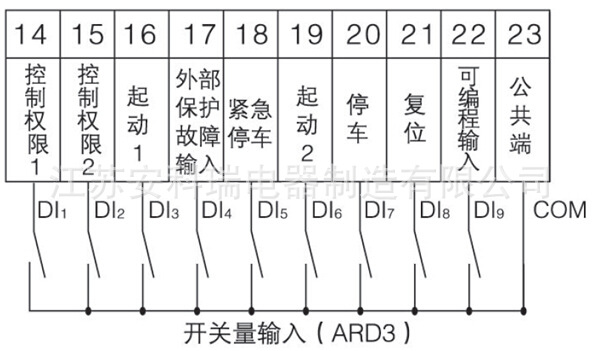

● 主体开关量类型

表 6

测量模块

表 7

附加功能

表 8

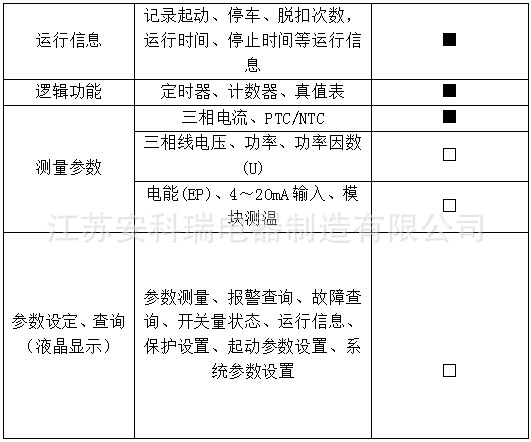

● 功能配置

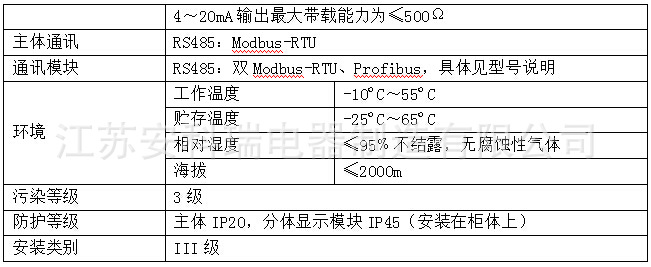

● 技术指标

2.3 产品介绍

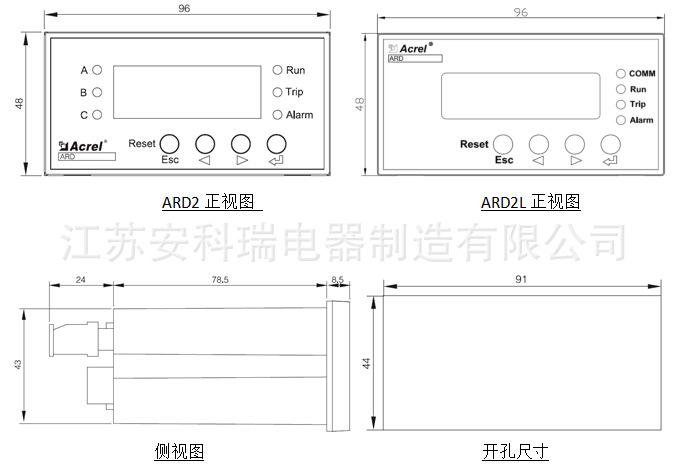

2.3.1 ARD2(L)电动机保护器

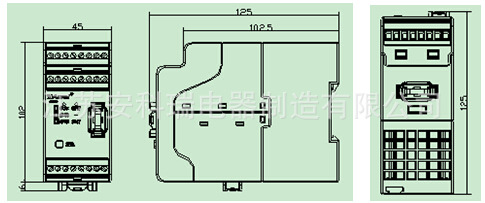

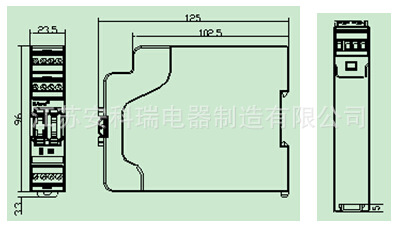

● 外形及安装尺寸(单位:mm)

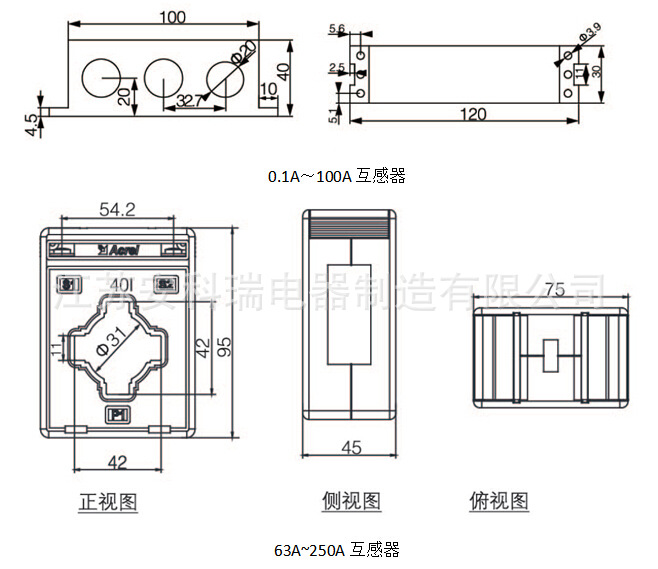

主体模块

互感器

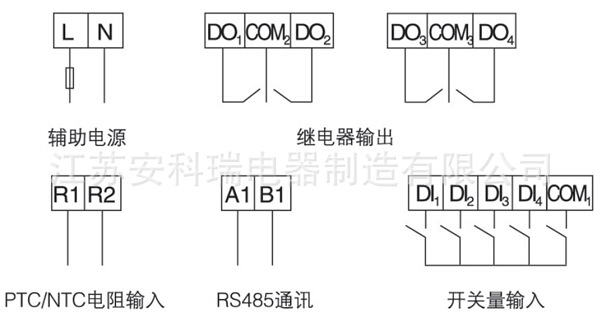

● 接线端子

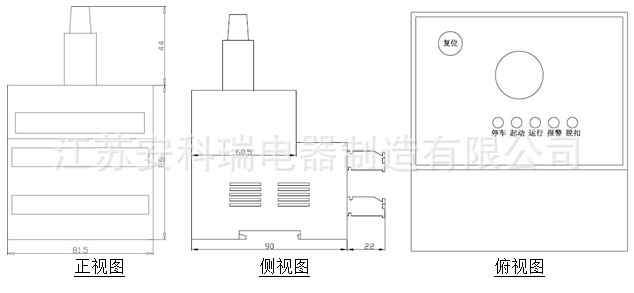

2.3.2 ARD2F、ARD3电动机保护器

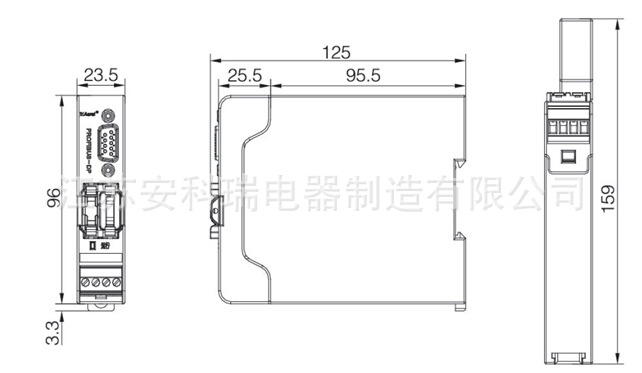

外形及安装尺寸(单位:mm)

主体模块

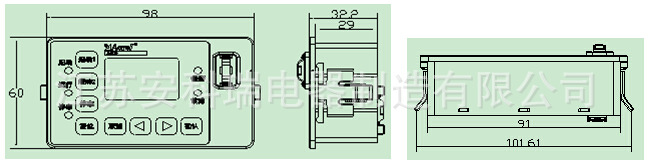

显示单元

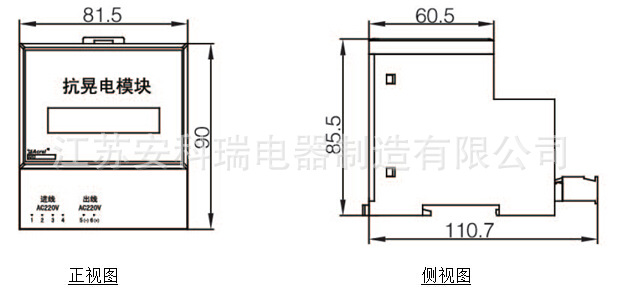

抗晃电模块

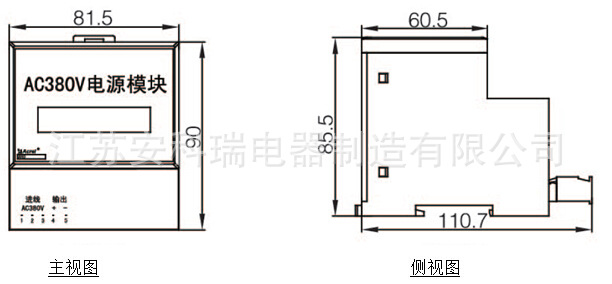

AC380V电源模块

互感器

同ARD2(L)互感器部分

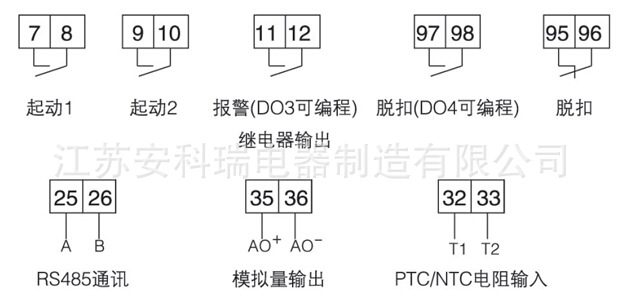

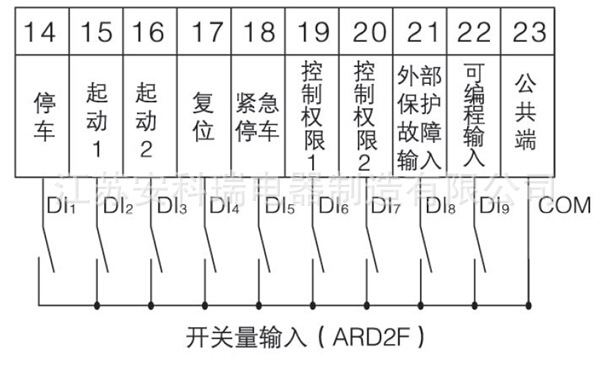

● 接线端子

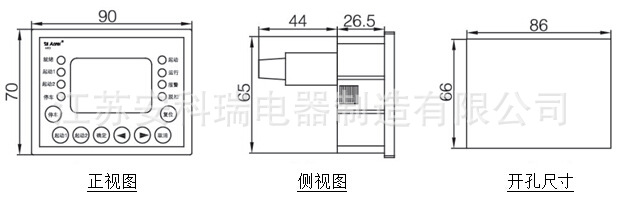

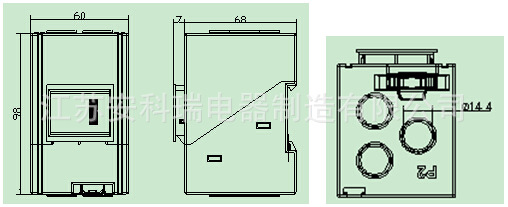

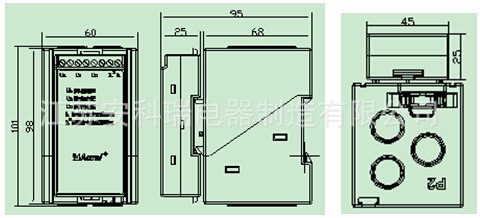

2.3.3 ARD3T电动机保护器

外形及安装尺寸(单位:mm)

主体模块:

测量模块:

电流测量模块

电流+电压测量模块

温度、模拟量、开关量模块:

通讯模块:

显示模块:

外置电流互感器:

漏电流互感器:

接线端子

主体模块

测量模块

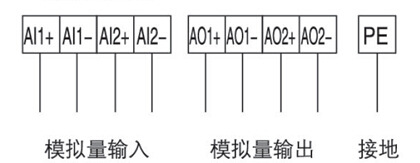

模拟量模块

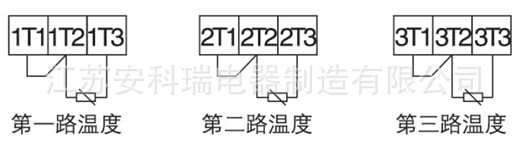

温度模块

二线制

三线制

开关量模块

通讯模块

● 简介

ARD2系列智能电动机保护器能对电动机运行过程中出现的起动超时、过载、断相、不平衡、欠载、接地/漏电、阻塞、短路、外部故障等多种情况进行保护,并设有SOE故障事件记录功能,方便现场维护人员查找故障原因。

● 产品功能

■ 测量

电流、电流不平衡度、剩余电流测量

■ 保护

过载、接地、起动超时、漏电、欠载、断相、堵转、阻塞、短路、不平衡(电流)、外部故障保护

■ 输入/输出

2路DI输入

4路DO输出

1路DC4-20mA模拟量输出

■ 通讯(选配)

1路MODBUS_RTU

■ 故障记录

■ 数码管/液晶显示界面可选

因为发电厂电机设备的使用量逐步增多,促使电动机的正常运转发挥成为了其他的设备能够正常运转的前提条件,因此能够合理选择和使用电动机控制器是对正常的工业现场生产工作负责的表现,只有在电动机正常发挥其功能的基础上,才能够保证整个电机设备的工作流程不会受到干扰,可以正常运行。在斯里兰卡某电厂中,给客户推荐我司的ARD2F系列。

Because the use of motor equipment in power plants is gradually increasing, the normal operation of the motor has become a prerequisite for the normal operation of other equipment. Therefore, the reasonable selection and use of motor controllers is responsible for normal industrial site production work. Only on the basis of the normal function of the motor, it can be ensured that the working process of the entire motor equipment will not be disturbed and can operate normally. In a power plant in Sri Lanka, we recommend our ARD2F series to customers.

在电厂电机设备的保护设计中,低压电动机的应用及保护配置可采用多种方案进行设计,对于过去采用热继电器、断路器(或熔断器)作为电动机过负荷保护、断相保护、短路保护和控制元件,我们ARD2F智能电动机控制器可实现重载起动,实现对电动机的温度保护,还提供多种测控功能和多种电动机控制模式,能够满足对电动机的保护控制要求,合理地保障了电机的安全运行。接下来我们介绍下ARD2F智能型电动机控制器在发电厂中的实际应用进行具体介绍。

In the protection design of power plant electrical equipment, the application and protection configuration of low-voltage motors can be designed with a variety of solutions. In the past, thermal relays, circuit breakers (or fuses) were used as motor overload protection, phase failure protection, short-circuit protection and Control components, our ARD2F intelligent motor controller can realize heavy load starting and realize the temperature protection of the motor. It also provides a variety of measurement and control functions and a variety of motor control modes, which can meet the protection and control requirements of the motor, and effectively protect the motor safe operation. Next, we introduce the actual application of the ARD2F intelligent motor controller in power plants for a specific introduction.

2.电厂对电动机控制器的功能要求

Functional requirements for motor controllers in the power plant

在电厂中,发电总量中消耗在电动机上的电量就占了很大一部分,而各类风机、水泵、空压机又占电动机所耗电的一半以上。由于发电厂电动机的工作环境较恶劣,经常容易发生堵转、短路、断相或长期过载运行等故障,所以急需一个可以对电机进行实时保护、控制,保证发电厂电动机的正常运行。

In power plants, the electricity consumed by motors accounts for a large part of the total power generation, and various types of fans, pumps, and air compressors account for more than half of the electricity consumed by motors. Due to the harsh working environment of the motors in power plants, they are often prone to faults such as locked rotor, short circuit, open phase or long-term overload operation, so there is an urgent need for a real-time protection and control of the motor to ensure the normal operation of the motor in the power plant.

因此,ARD2F可以对电厂电机进行电压、电流全电量参数测量,并且带通讯功能,控制器需要有自诊断输出、断电输出、故障记录等功能,总结为如下功能:

Therefore, ARD2F can measure the voltage and current full power parameters of the power plant motor, and has communication functions. The controller needs to have functions such as self-diagnosis output, power-off output, and fault recording, which are summarized as the following functions:

1.实现完善的电机保护功能 Realize complete motor protection function

控制器通过采集三相交流电流、三相交流电压、剩余电流、PTC热电阻阻值、电动机电能等电量参数,以及电动机运行过程中的各种运动状态等信号,经控制器内部处理运算,从而实现对电动机起动超时、过载、阻塞、欠载、断相、三相电流不平衡、剩余电流(接地/漏电)、温度、外部故障、相序、过压、欠压、欠功率、过功率、tE时间等全方面综合保护,进而保证发电厂生产工作的安全连续运行。

The controller collects three-phase AC current, three-phase AC voltage, residual current, PTC thermal resistance resistance, motor electrical energy and other electrical parameters, as well as signals such as various motion states during the operation of the motor, and then processes and calculates internally by the controller. Realize the motor starting overtime, overload, blockage, underload, phase failure, three-phase current imbalance, residual current (ground/leakage), temperature, external fault, phase sequence, overvoltage, undervoltage, underpower, overpower, Comprehensive comprehensive protection such as tE time, and then ensure the safe and continuous operation of the power plant production work.

2.实现多种电动机控制方式 Realize a variety of motor control methods

智能型电动机控制器通过程序控制,实现多种不同的电动机起动控制,采用控制器来实现的操作控制权限包括:1)RS-485通讯接口实现远程控制;2)能够通过显示模块上的按键进行操作控制;3)通过DCS系统控制DI端子实现远程自动控制;4)DI端子现场就地控制。

The intelligent motor controller realizes a variety of different motor starting control through program control. The operation control authority realized by the controller includes: 1) RS-485 communication interface to realize remote control; 2) It can be carried out through the buttons on the display module Operation control; 3) Realize remote automatic control through DCS system control DI terminal; 4) DI terminal on-site control.

3.实现现场实时监测电动机运行 Realize real-time monitoring of motor operation on site

电厂通过控制器能够实时观察现场电动机设备在运行过程中的电压、电流、频率等参数以及电动机当前的运行状况,操作显示模块上的按键设置电厂电动机设备的起动方式(可选择手步启动、两步启动、双速启动和保护方式)。

Through the controller, the power plant can observe the voltage, current, frequency and other parameters of the field motor equipment in the running process and the current operating status of the motor in real time. Operate the buttons on the display module to set the starting mode of the power plant motor equipment (optional manual start, two Step start, two-speed start and protection mode).

4.实现通讯功能 Realize communication function

控制器可通过RS-485通讯接口,经过Modbus-RTU或Profibus-DP通讯协议与上位机管理系统进行通讯连接,将信息在较短时间内发送给后台管理系统并对故障信息发出报警信号,使操作人员能够尽快发现故障原因并及时排除故障,实现电厂电动机设备的数据的实时传输功能。

The controller can communicate with the upper computer management system through the RS-485 communication interface through the Modbus-RTU or Profibus-DP communication protocol, and send the information to the background management system in the shortest time and send an alarm signal to the fault information to make the operation The personnel can find the cause of the fault and eliminate the fault in time to realize the real-time transmission function of the data of the electric motor equipment of the power plant.

ARD2F智能型电动机控制器采用模块化的产品结构形式,包括主体控制模块、互感器模块和显示模块,并可根据工业现场的实际应用选配ARD2F智能型电动机控制器的其他功能模块和附件。

ARD2F intelligent motor controller adopts modular product structure, including main control module, transformer module and display module, and can be equipped with other functional modules and accessories of ARD2F intelligent motor controller according to the actual application of the industrial field.

3.电厂选用ARD2F智能型电动机控制器产生的效果

The effect of using ARD2F intelligent motor controller in power plant

对电动机的运行实施保护以及保证电动机能够连续不间断的运行对于生产是至关重要的,电厂选用ARD2F智能型电动机控制器后带来的好处有:

Protecting the operation of the motor and ensuring the continuous and uninterrupted operation of the motor are vital to production. The benefits of using the ARD2F intelligent motor controller for power plants include:

1.组网灵活性高,便于控制 High networking flexibility, easy to control

电厂中电动机控制器与配电产品的应用有着相同的比重,在实现组网的工作过程中,它们是密不可分的。ARD2F智能型电动机控制器提供了RS-485通讯接口,并且实现多种协议的选择(Modbus-RTU/Profibus-DP),通过RS-485与上位机之间的通信,能够方便工程师通过计算机后台实现远程自动控制和在线监视设备的运行状况等。

The application of motor controllers and power distribution products in power plants has the same proportions, and they are inseparable in the process of realizing the networking. ARD2F intelligent motor controller provides RS-485 communication interface, and realizes the choice of multiple protocols (Modbus-RTU/Profibus-DP). Through the communication between RS-485 and the host computer, it is convenient for engineers to realize through the computer background Remote automatic control and online monitoring of equipment operation status, etc.

2.实时显示参数,方便现场巡检 Real-time display of parameters, convenient on-site inspection

ARD2F智能型电动机控制器是采用模块化的产品结构形式,将显示模块安装在DCS柜体,通过液晶界面即可实时观察当前电动机的运行状态,便于用户对现场电动机的维护和控制。

The ARD2F intelligent motor controller adopts a modular product structure. The display module is installed in the DCS cabinet, and the current running status of the motor can be observed in real time through the LCD interface, which is convenient for users to maintain and control the on-site motor.

3.节能降耗 Energy saving

电动机控制器在节能降耗方面的作用开始为大家所重视,ARD2F智能型电动机控制器可以在电动机设备处于欠载等运行状态时做自动停机,合理的避免了能源的浪费,为企业节省资金。

The role of the motor controller in energy saving and consumption reduction began to be paid attention to. The ARD2F intelligent motor controller can automatically stop when the motor equipment is under load and other operating conditions, effectively avoiding the waste of energy and saving money for the enterprise.

4.信息集中化 Information centralization

用户可通过通讯模块实现在后台实时监测系统中各个电动机的运行状况,随时观察设备的运行参数,如:电动机电流、电压、电动机运行状况、电动机电能等参数,通过分析采集到的信息,用户可以对各个设备的电动机运行情况进行实时处理,提高了整个控制系统的安全性、可靠性。

The user can monitor the operating status of each motor in the system in real time through the communication module, and observe the operating parameters of the equipment at any time, such as: motor current, voltage, motor operating status, motor power and other parameters. By analyzing the collected information, the user can Real-time processing of the motor running status of each device improves the safety and reliability of the entire control system.

5.智能化自控保护 Intelligent automatic control protection

ARD2F智能型电动机控制器使用灵活,报警和保护参数可以通过软件根据电厂电动机设备实际运行条件预设不同的值,避免因过度保护影响实际生产。用户在选用ARD2F智能型电动机控制器后,一旦现场电动机出现故障,控制器及时控制电动机停止运行,并对各种故障信息作出相应的指示和记录,方便用户查询故障信息。在电网故障造成电压瞬间较大幅度的波动或者短时断电又恢复,带抗晃电功能时可使电动机控制器重新起动。

The ARD2F intelligent motor controller is flexible to use. The alarm and protection parameters can be preset to different values through the software according to the actual operating conditions of the power plant's motor equipment, so as to avoid excessive protection from affecting actual production. After the user selects the ARD2F intelligent motor controller, once the on-site motor fails, the controller controls the motor to stop running in time, and makes corresponding instructions and records of various fault information, so that the user can query the fault information. When the grid fault causes a large voltage fluctuation or short-term power failure and recovery, the motor controller can be restarted with the anti-shake function.

6. 记录电机故障信息,便于现场问题分析

Record motor fault information for easy on-site problem analysis

在发电厂工作的电动机设备大多数处于高温、潮湿、多尘埃的工况下,很容易出现故障,一旦发生故障,检修人员也很难尽快发现故障原因,并且需要一定的时间、人力和物力才能分析故障原因。ARD2F智能型电动机控制器有强大的故障和事件记录、运行管理信息为现场维护人员节省了大量的时间,提高了维修人员的工作效率,进一步提高了整个控制回路的性能。

Most of the motor equipment working in power plants are in high temperature, humidity, and dusty conditions, which are prone to failure. Once a failure occurs, it is difficult for maintenance personnel to find the cause of the failure in the first time, and it takes a certain amount of time, manpower and Material resources can analyze the cause of the failure. The ARD2F intelligent motor controller has powerful fault and event records and operation management information, which saves a lot of time for field maintenance personnel, improves the work efficiency of maintenance personnel, and further improves the performance of the entire control loop.

4.小结 Summary

在发电厂低压电动机保护和监控系统中采用ARD2F智能型电动机控制器,在提高控制回路的自动化水平和可靠性的同时也提高了企业的综合效益,做到了可靠性和经济性的统一。并且,随着技术的不断发展,ARD2F智能型电动机控制器在发电厂低压电动机保护及测控运行过程中将起到越来越大的作用。

The ARD2F intelligent motor controller is used in the low-voltage motor protection and monitoring system of the power plant, which not only improves the automation level and reliability of the control loop, but also improves the comprehensive benefits of the enterprise, and achieves the unity of reliability and economy. Moreover, with the continuous development of technology, ARD2F intelligent motor controller will play an increasingly important role in the protection and measurement and control of low-voltage motors in power plants.