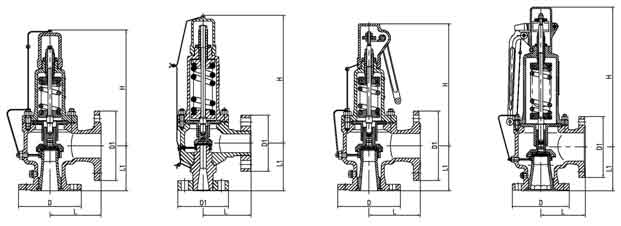

全启式安全阀概述:

上海富通阀门制造有限公司是国内生产安全阀的主导厂,厂内建有远东*的安全阀测试中心,国产*台安全阀就是我厂诞生的。二十多年来,富通牌安全阀的品种已发展到百余个系列,千余个规格,产品广泛应用于锅炉、石化、电站以及国防工业。并为国内*座核电站秦山核电站研制成功了*批核级安全阀。高桥牌安全阀主要产品系列分别荣获机械部信得过产品,上海市优质产品称号,国家银质奖。 富通牌安全阀是受压设备、容器或管路上的*超压保护装置。当设备压力升高达到预定值时,安全阀自动开启,继而全量排放,防止设备压力继续升高;当压力降低到规定值时,安全阀及时自动关闭。富通牌安全阀是选用者为保护工程设备安全运行的的,zui科学的明智选择。 主要连接尺寸: | 型 号 | 公称 | 主要结构尺寸(mm) | 阀体

材料 | 简要性能 | 备注 | | 通径

DN(mm) | 压力

PN(Mpa) | D | D1 | L | L1 | H | 适用温度

℃ | 适用介质 | | A42Y-16C | 32 | 1.6 | 135 | 146 | 115 | 110 | 285 | 铸钢 | ≤300 | 油品、空气等 | | | " | 40 | " | 150 | 160 | 120 | 110 | 278 | " | " | " | | | " | 50 | " | 165 | 180 | 135 | 120 | 332 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 200 | 215 | 170 | 135 | 478 | " | " | " | | | " | 100 | " | 220 | 245 | 205 | 160 | 590 | " | " | " | | | " | 150 | " | 280 | 310 | 255 | 230 | 650 | " | " | " | | | " | 200 | " | | | | | | " | " | " | | | A42Y-40 | 32 | 4.0 | 140 | 150 | 115 | 100 | 285 | 铸钢 | ≤300 | 油品、空气等 | | | " | 40 | " | 145 | 160 | 130 | 120 | 278 | " | " | " | | | " | 50 | " | 160 | 180 | 145 | 130 | 332 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 195 | 215 | 170 | 150 | 478 | " | " | " | | | " | 100 | " | 230 | 245 | 205 | 185 | 590 | " | " | " | | | " | 150 | " | 300 | 310 | 255 | 230 | 650 | " | " | " | | | " | 200 | " | | | | | | " | " | " | | | A42Y-64 | 32 | 6.4 | | | | | | 铸钢 | ≤300 | 油品、空气等 | | | " | 40 | " | 165 | 160 | 130 | 120 | 308 | " | " | " | | | " | 50 | " | 175 | 180 | 155 | 130 | 464 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 210 | 230 | 175 | 160 | 582 | " | " | " | | | " | 100 | " | 250 | 270 | 195 | 195 | 600 | " | " | " | | | A42Y-100 | 32 | 10.0 | | | | | | 铸钢 | ≤300 | 油品、空气等 | | | " | 40 | " | | | | | | " | " | " | | | " | 50 | " | 195 | 180 | 155 | 130 | 500 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 230 | 230 | 175 | 160 | 760 | " | " | " | | | " | 100 | " | 265 | 270 | 220 | 210 | 750 | " | " | " | | | SA42Y-160 | 32 | 16.0 | 115 | 165 | 150 | 150 | 397 | 铸钢 | ≤200 | 氮、氨气、油品、空气 | | | " | 40 | " | 165 | 200 | 165 | 165 | 438 | " | " | " | | | SA42Y-320 | 32 | 3.2 | 135 | 165 | 150 | 150 | 395 | 铸钢 | ≤200 | 氮、氨气、油品、空气 | | | " | 40 | " | | | | | | " | " | " | | | SA42Y-400 | 32 | 40.0 | 135 | 165 | 150 | 150 | 397 | 铸钢 | ≤200 | 氮、氨气、油品、空气 | | | " | 40 | " | | | | | | " | " | " | | | A44Y-16C | 32 | 1.6 | | | | | | 铸钢 | ≤300 | 油品、空气等 | | | A44Y-16C | 80 | 1.6 | 200 | 220 | 170 | 135 | 538 | 铸钢 | ≤300 | 油品、空气等 | | | " | 100 | " | 215 | 245 | 205 | 185 | 655 | " | " | " | | | " | 150 | " | 280 | 310 | 255 | 230 | 740 | " | " | " | | | " | 200 | " | | | | | | " | " | " | | | A44Y-40 | 32 | 4.0 | | | | | | 铸钢 | ≤300 | 油品、空气等 | | | " | 40 | " | 145 | 165 | 130 | 120 | 314 | " | " | " | | | " | 50 | " | 160 | 180 | 145 | 130 | 376 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 195 | 215 | 170 | 150 | 538 | " | " | " | | | " | 100 | " | 230 | 245 | 205 | 185 | 655 | " | " | " | | | " | 150 | " | 300 | 310 | 255 | 230 | 740 | " | " | " | | | " | 200 | " | | | | | | " | " | " | | | A44Y-64 | 32 | 6.4 | | | | | | 铸钢 | ≤300 | 油品、空气等 | | | " | 40 | " | | | | | | " | " | " | | | " | 50 | " | 175 | 180 | 155 | 130 | 520 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 210 | 230 | 175 | 160 | 810 | " | " | " | | | " | 100 | " | 250 | 270 | 195 | 195 | 890 | " | " | " | | | A44Y-100 | 32 | 10.0 | | | | | | 铸钢 | ≤300 | 油品、空气等 | | | " | 40 | " | | | | | | " | " | " | | | " | 50 | " | 195 | 180 | 155 | 130 | 520 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 230 | 230 | 175 | 160 | 810 | " | " | " | | | " | 100 | " | 265 | 270 | 220 | 210 | 780 | " | " | " | | | A48Y-16C | 32 | 1.6 | | | | | | 铸钢 | ≤350 | 蒸气等 | | | " | 40 | " | 145 | 160 | 130 | 115 | 312 | " | " | " | | | " | 50 | " | 160 | 180 | 145 | 130 | 366 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 195 | 215 | 170 | 150 | 528 | " | " | " | | | " | 100 | " | 215 | 245 | 205 | 185 | 655 | " | " | " | | | " | 150 | " | 280 | 310 | 255 | 230 | 724 | " | " | " | | | " | 200 | " | | | | | | " | " | " | | | A48Y-40 | 32 | 4.0 | | | | | | 铸钢 | ≤350 | 蒸气等 | | | A48Y-64 | 32 | 6.4 | | | | | | 铸钢 | ≤350 | 蒸气等 | | | " | 40 | " | | | | | | " | " | " | | | " | 50 | " | 175 | 180 | 155 | 130 | 508 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 210 | 230 | 175 | 160 | 655 | " | " | " | | | " | 100 | " | 250 | 270 | 195 | 195 | 680 | " | " | " | | | A48Y-100 | 32 | 10.0 | | | | | | 铸钢 | ≤350 | 蒸气等 | | | " | 40 | " | | | | | | " | " | " | | | " | 50 | " | 195 | 180 | 160 | 130 | 508 | " | " | " | | | " | 65 | " | | | | | | " | " | " | | | " | 80 | " | 180 | 230 | 175 | 160 | 655 | " | " | " | | | " | 100 | " | 265 | 270 | 220 | 210 | 785 | " | " | " | | | SFNA-42B25C1 | 32 | " | 195 | | | 120 | 185 | 锻钢 | ≤55 | 液化气 | | | " | 40 | " | 230 | | | 100 | 205 | " | " | " | | | " | 50 | " | 270 | | | 104 | 250 | " | " | " | 制造标准:中国GB、机械部JB、化工标准HG、美标API、ANSI、德标DIN、日本JIS、JPI、英标BS生产。阀体材质:铜、铸铁、铸钢、碳钢、WCB、WC6、WC9、20#、25#、锻钢、A105、F11、F22、不锈钢、304、304L、316、316L、铬钼钢、低温钢、钛合金钢等。工作压力1.0Mpa-50.0Mpa。工作温度:-196℃-650℃。连接方式:内螺纹、外螺纹、法兰、焊接、对焊、承插焊、卡套、卡箍。驱动方式:手动、气动、液动、电动。上海富通阀门制造有限公司拥有zui*的生产设备和技术工程师,有能力按照各国标准以及各种行业标准生产制造优质阀门。 |